NTN Exhibits at “JIMTOF2014 The 27th Japan International Machine Tool Fair”October 16, 2014

| Date | October 30 (Thu) to November 4 (Tue), 2014 |

|---|---|

| Venue | Tokyo Big Sight |

| Booth No. | W2062 |

NTN will run a booth at “JIMTOF2014 The 27th Japan International Machine Tool Fair” with the theme “Delivering monozukuri with proprietary technology.” The booth will be separated into three zones: “Proposals for precision bearing and technology for machine tools” “Initiatives in the aftermarket” and “Proposals of new technology” to showcase NTN's proprietary technology and products.

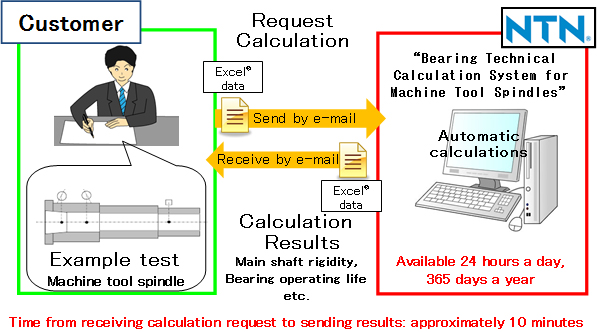

In the “Proposals for precision bearing and technology for machine tools” zone, exhibits will be centered around the ULTAGE* series of bearings that deliver “Long life,” “High speed & high rigidity,” “High precision” and “Enviromental conservation,” as well as demonstrations of the industry's first Bearing Technical Calculation System for Machine Tool Spindles that uses email. Be sure to check out the easy-to-use and convenient system that quickly and automatically calculates main shaft rigidity, bearing operating life and other features.

In the “Initiatives in the aftermarket” zone, various maintenance tools will be on display including a demonstration area to highlight how to use them.

The “Proposals of new technology” zone will feature exhibits such as the ULTAGE series of rolling bearings for industrial machinery, composite material products, as well as the Parallel link high. speed Angle Control Equipment. Technology used to monitor and diagnose bearing conditions will also be exhibited, including the Condition Monitoring System for wind turbines (CMS) known as “Wind Doctor™” and the Handy Type Failure Detection Device.

We look forward to seeing you at the event.

| * | ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the [ULTIMATE] performance on any type of [STAGE.] It represents NTN's goal of achieving the ultimate performance with precsion bearings. |

Main exhibits

ULTAGE series of precision rolling bearings for machine tools

Precision bearings responding to the need for improved efficiency, reliability, quality and environmental responsibility for machine tools. Optimization of the bearing's internal design, as well as special material and surface improvements, special grease and the use of seals on both sides deliver outstanding performance.

Also the newly developed “High Speed Angular Contact Ball Bearings HSE-NEW T2 Type” for machine tool main spindles delivering a high-speed rotation with a dmn* value of 1.6 million through the use of a new plastic retainer will be on display.

| *dmn value | : | Index that represents bearing rotation performance, bearing pitch circle diameter (mm) × rotational speed (min-1) |

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Reduces the difference in temperature between the inner and outer rings with the use of an “air cooling spacer” using proprietary air cooling technology suited to bearing for main spindle of machine tools. This improves the high-speed rotational performance by 20% compared to conventional products (High-speed Angular Contact Ball Bearings), and achieves a dmn value of 2.1 million to achieve the world's highest standard high-speed rotational performance with air-oil lubrication and fixed-position preload.

Bearing Technical Calculation System for Machine Tool Spindles

Designed for precision rolling bearings used for machine tool spindles, this system that allows customers to quickly and automatically calculate main shaft rigidity, bearing operating life and other features will be on show for the first time. 10 types of main shaft patterns can be calculated, and the dedicated server operates 24 hours a day, 365 days a year for use at any time.

Maintenance tools

ULTAGE series of rolling bearings for industrial machinery

Composite material products

Parallel link High speed Angle Control Equipment

A proprietary link mechanism and newly developed drive mechanism achieve high-speed and high-precision positioning over a wide range of moving angles.

Condition Monitoring System for wind turbines “Wind Doctor™”

CMS featuring the world's smallest class of data collection device, measurement sensor, and data control, monitoring and analysis software. First in Japan to acquire GL certification (certification system developed for wind turbines).

Handy Type Failure Detection Device

By using a smartphone, bearing vibration data is sent over the internet to a server, where it is calculated and analyzed. The input and output is also displayed on the smartphone, which makes for extremely compact and portable vibration measurement system.

IC Tag Integrated Bearing

The industry's first product that allows information to be recorded and read with an IC tag built into the bearing and a special reader/writer unit. The type of information saved can be configured for each user, allowing bearing quality information, as well as inspection records, to be checked.