Enhancements to the “Parallel Link High Speed Angle Control Equipment” for High-speed, High-precision PositioningNovember 7, 2014

[Greater ease of maintenance for greater user-friendly operation]

NTN Corporation (hereafter, NTN) had been manufacturing and marketing the “Parallel link High speed Angle Control Equipment*1,” a compact device that allows high-speed, high-precision positioning over a wide range of moving angles, and has now made enhancements to the structure to develop a product with even higher speed and higher precision positioning, as well as greater ease of maintenance.

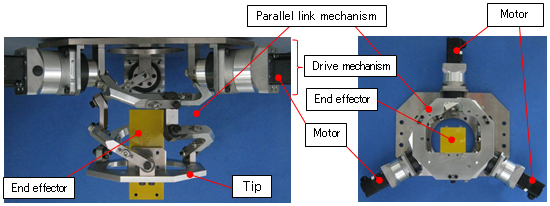

The “Parallel link High speed Angle Control Equipment” developed by NTN uses a special parallel link mechanism*2. This allows the associated device to be compact and move over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. The conventional product had moving parts (end effector) mounted to the end of the parallel link mechanism, however the improved product features the end effector mounted within the mechanism itself. As a result, the moment of inertia acting on the end effector is reduced with the positioning speed and precision increased by approximately 10% compared to the conventional product, to achieve even higher speed and higher precision positioning. The overall height of the device has been shortened by approximately 10%, and the overall length has also been made more compact. The drive mechanism features a more simple design which allows the connector cable for the end effector to be installed within the mechanism, which makes maintenance and wiring work easier.

Improvements have also been made to work efficiency based on feedback on the conventional product received from worksites, including teaching, movement settings and setup changes using a dedicated teaching console.

The developed product was exhibited at “JIMTOF2014 The 27th Japan International Machine Tool Fair” held at Tokyo Big Sight from October 30 to November 4, and will be marketed as the enhanced version of the device that helps to improve productivity of automated production equipment that requires high-speed, high-precision positioning over a wide range of moving angles, in a space-efficient package.

| *1) | 2012 press release: |

| https://www.ntnglobal.com/en/news/new_products/news201200004.html | |

| *2) | Mechanism comprising of three sets of similar link systems between the moving and stationary link hubs. Each link system consists of a rotating L-shaped arm attached to the outer circumference of the moving and stationary link hubs, and a rotatably connected intermediate link connecting the axis of rotation of the end of each hub in a single location. |

Features

Enhancements made to the angle control device that allows high-speed positioning to a target location from a wide range of angles

| (1) | Greater productivity | |

| · | Shorter takt time | |

| Less moment of inertia for approximately 10% improvement to positioning speed and precision compared to the conventional product (positioning of 12 points per second) | ||

| · | Less downtime | |

| Improvements to work efficiency, including teaching, movement settings and setup changes with a dedicated teaching console | ||

| (2) | More compact | |

| · | Approximately 10% reduction in overall device height with the same range of movement as the conventional product | |

Application

Grease or adhesive applicators, painting equipment, welders and other devices

Inquiries about this release

Product photo

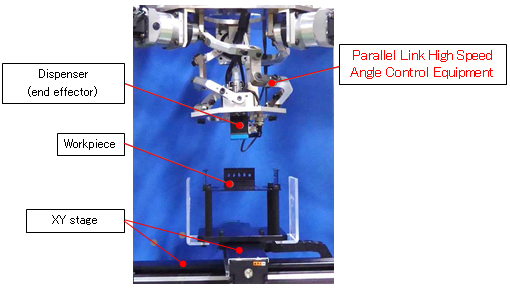

Example of applications

Grease applicator

Demonstration of operation (video)

Demonstration of operation of high-speed automatic grease applicator (zoomed)

(coordinated operation with XY stage with loaded work piece)

Demonstration of operation of high-speed automatic grease applicator (overall)

(coordinated operation with XY stage with loaded work piece)