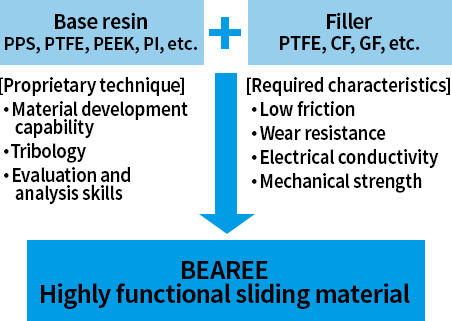

Features of BEAREE

- Solve issues regarding wear and friction by customizing filler and base resin such as engineering plastic or super engineering plastic

- Have characteristics of low friction or wear resistance, electrical conductivity for shaft grounding and removal of static electricity, and seal characteristic for fluid and gas, as well as compatible with water and chemicals

- Available in optimal material and design specification according to usage conditions such as mating material, surface pressure, speed, and lubrication

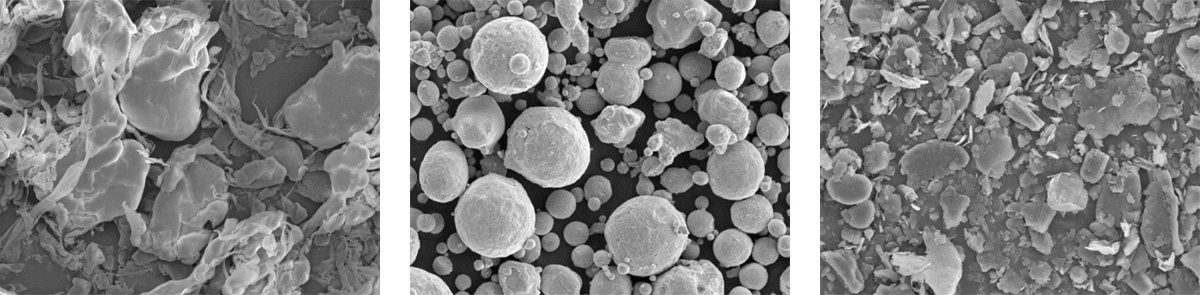

Enlarged view of filler

For Replacement of Metal Material

As BEAREE is plastic material, it is lighter than metal material and has a variety of other characteristics.

| Plastic | Metal | |

|---|---|---|

| Mass | Light | Heavy |

| Self-lubricating | Yes | None |

| Water resistance (rust) | Yes | None |

| Flexibility | Yes | None |

| Design flexibility | Yes | Less |

| Electrical insulation | Yes | None |

- ※In addition to the above, plastic material is characterized by lower in load resistance, strength, elastic modulus, and dimensional accuracy than metal material, as well as large dimensional changes due to temperature.

Product Lineup

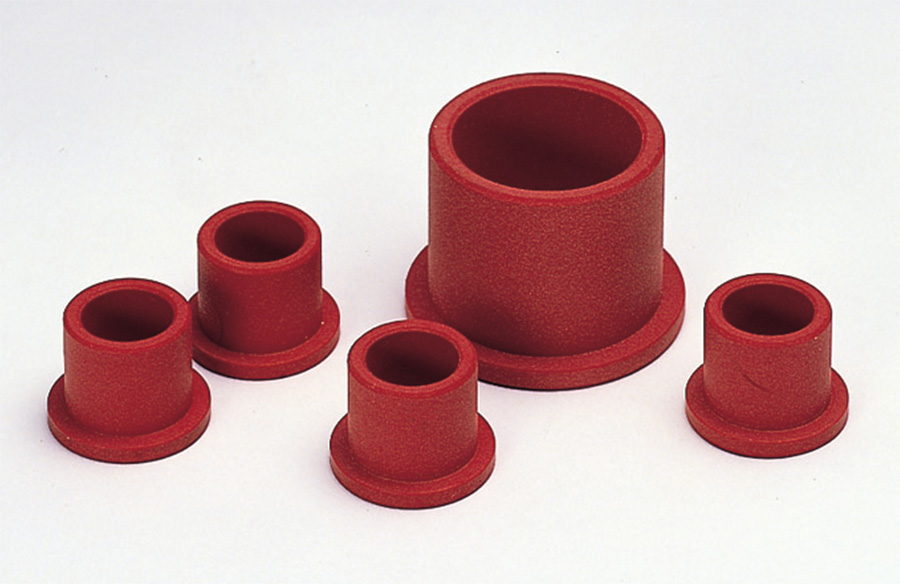

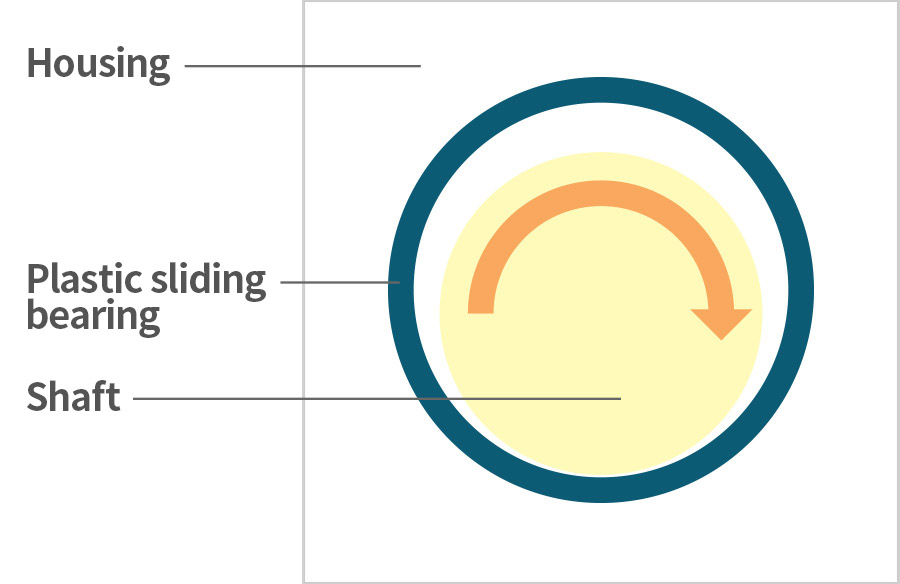

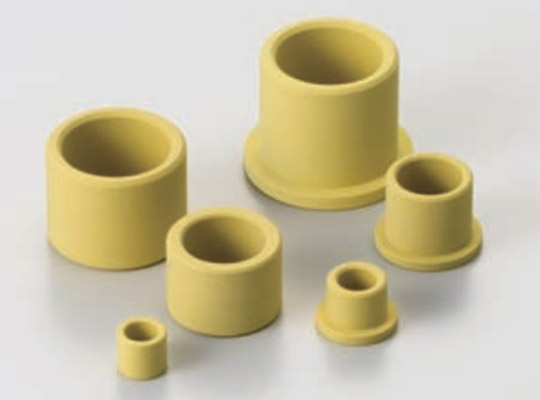

Sliding bearing

- Bearing made from plastic material, supporting shaft or sliding surface on axis

- Feature low coefficient of friction, reducing power loss

- Lighter and more flexible in design than metal material

- Less likely to transmit vibration and noise

- Excellent with workability with heating, electrical insulation, and water and chemical resistance

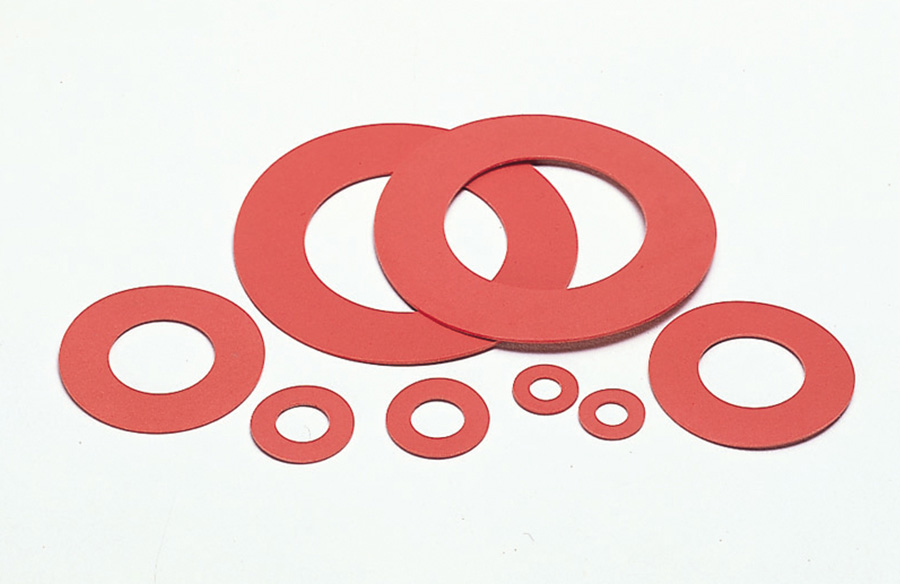

Sliding seal

- Excellent wear resistance and low friction

- High fitness and excellent sealing for gas and oil

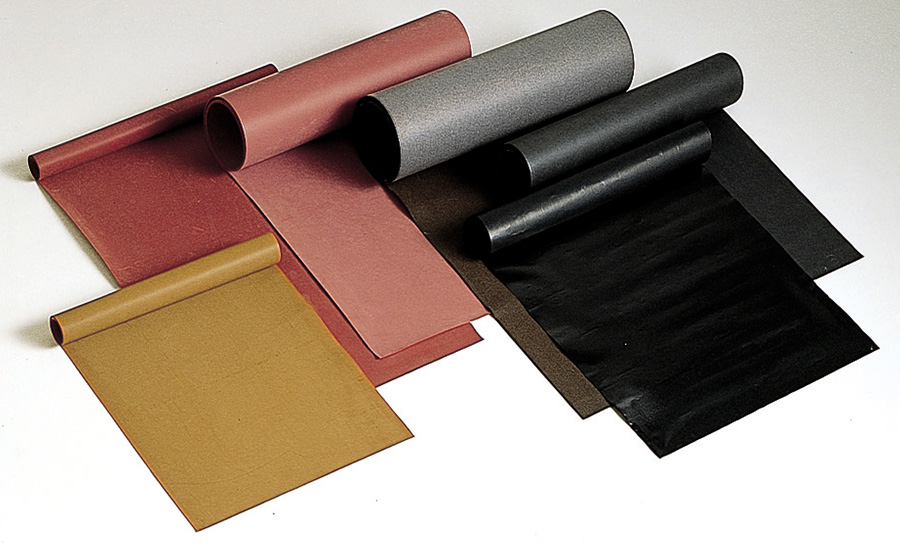

Sheet material/Rod material/Pipe material

- Sheet material: Can be used for various applications including washers and pad through punching and cutting by users

- Rod/Pipe material: Can be used in variety applications including sliding bearing through turning processing and milling by users

Sheet material

Rod material

Pipe material

Sliding screw

- Convert rotational motion to linear motion

- Achieve superior quietness and efficiency by adopting proprietary low friction and low wear plastic material in nut

- Applicable to various conditions because of lubrication-free, corrosion resistance, and heat resistance

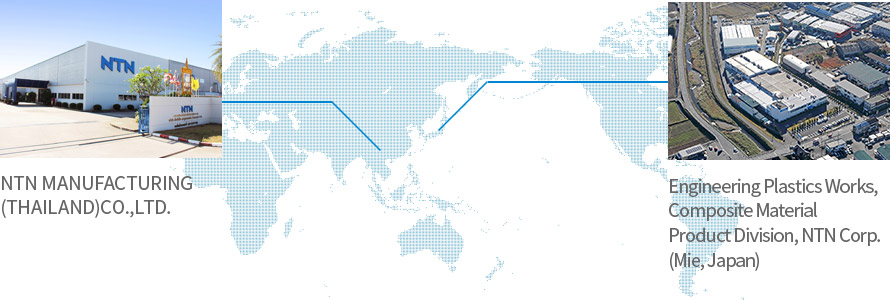

Global Production System

We produce high precision products at Engineering Plastics Works in Japan and NTN MANUFACTURING (THAILAND)CO., LTD. to respond to demand globally.

Typical Material Characteristics

Sliding bearing

| Grade | Base resin | Characteristics |

|---|---|---|

| FL3000 | PTFE |

|

| FL3030 | PTFE |

|

| FL3700 | PTFE |

|

| AS5005 | PPS |

|

| AS5704 | PPS |

|

Sliding seal

| Grade | Base resin | Characteristics |

|---|---|---|

| FL3000 | PTFE |

|

| FL3030 | PTFE |

|

| FL3082 | PTFE |

|

| AS5303 | PPS |

|

| PK5301 | PEEK |

|

Sheet material/Rod material/Pipe material

| Grade | Base resin | Characteristics |

|---|---|---|

| FL3000 | PTFE |

|

| FL3020 | PTFE |

|

| FL3030 | PTFE |

|

| FL3040 | PTFE |

|

| FL3307 | PTFE |

|

| FL3700 | PTFE |

|

| UH3954 | UHMWPE |

|

Sliding screw

| Grade | Base resin | Characteristics |

|---|---|---|

| AS5000 | PPS |

|

Standard Series

We have a lineup of low-cost standard series that do not require the fabrication of molds.

Sliding bearing

| Type | Appearance | Characteristics |

|---|---|---|

| ARE,AR [Sleeve bearing] Product catalog |

|

ARE is an emission-free environmentally friendly product machined from BEAREE FL3000 material using the auto molding method, with a bore size of φ3 to φ12 mm. AR is machined from a bar or pipe made of BEAREE FL3000 material. This bearing only carries radial load and the standard bore size is φ15 to φ50mm. |

| ARF [Flanged sleeve bearing] Product catalog |

|

ARF adds a flange to type AR and can carry radial and axial load. The standard inner diameter ranges φ3 to φ50mm. |

| BRF [Flanged sleeve bearing] Product catalog |

|

BRF is made by injection molding and its material is BEAREE AS5005. This bearing is flanged to carry radial and axial load. The standard inner diameter ranges from φ3 to φ25mm. |

| TW [Thrust washer] Product catalog |

|

TW thrust washer is made from BEAREE FL3000 sheet, the thickness is 0.8mm and standard bore is φ6 to φ50mm. |

| MLE[MLE bearing] Product catalog |

|

MLE is a bearing with a three-layer structure that is made by sintering bronze powder on a steel plate and impregnating it with polytetrafluoroethylene resin containing a special filler. The inner diameter of the radial load bearing MLE is standardized to φ60mm or less. The surface of the steel plate has tin coating for rust prevention. |

| ML [M liner bearing] Product catalog |

|

ML is a rolled steel plate bushing with BEAREE FL3060 liner bonded on its bore. This bearing carries higher pressure than types AR or ARF, having a thin wall, and a more compact design is possible. The standard bore size is φ3 to φ70mm and several widths are available for each bore. The surface of the steel plate has zinc coating for rust prevention. |

Sheet material/Rod material/Pipe material

| Type | Appearance | Characteristics |

|---|---|---|

| Sheet material Product catalog |

|

Sheet material is skived (turned) from a large billet made by compression molding. Surface treatment (etching) is required to make the sheet bondable. In the case of using the sheet to bond with adhesives, the material should be handled throught he surface treatment. BEAREE UH3954 cannot be etched. For BEAREE FL3307, one side of the sheet is processed for bonding. |

| Rod material Product catalog |

|

Round, rod shaped material made from ram extrusion molding. You can process the ordered shape to be made by turning or milling. |

| Pipe material Product catalog |

|

Pipe shaped material made from ram extrusion molding. You can process the ordered shape to be made by turning or milling. |

Sliding screw

| Type | Appearance | Characteristics |

|---|---|---|

| MSS [Miniature plastic sliding screw] Product catalog |

|

MSS is the sliding screw composed of BEAREE AS5000 nut and the screw shaft is made of SUS304.It can achieve low noise. The standard dimensions are: screw shaft nominal outside diameter of φ4~12mm with lead of 1 and 2mm.The leads of one and a half times and three times the shaft diameter are standard. |

Application Examples

Automobile (Car with Engine, HEV/EV)

Grounding

Sliding Parts for grounding electric corrosion countermeasure (proposed product)

Sliding parts that have been adopted as applications to eliminate static electricity from shafts. Now we propose this product as grounding parts for shaft and peripheral parts that involve sliding motion.

Electronic reclining seat

MLE bearing for reclining seat

It realizes excellent load and wear resistance with three-layer structure of steel plate, sintered layer and resin layer. It is lighter weight and more space saving when replacing radial needle bearings.

Suspension

Piston ring

It is attached to the outer diameter of the piston and seals oil while reciprocating.

It has stable low friction characteristics in oil and can be used for sliding with soft mating material such as stainless steel (SUS).

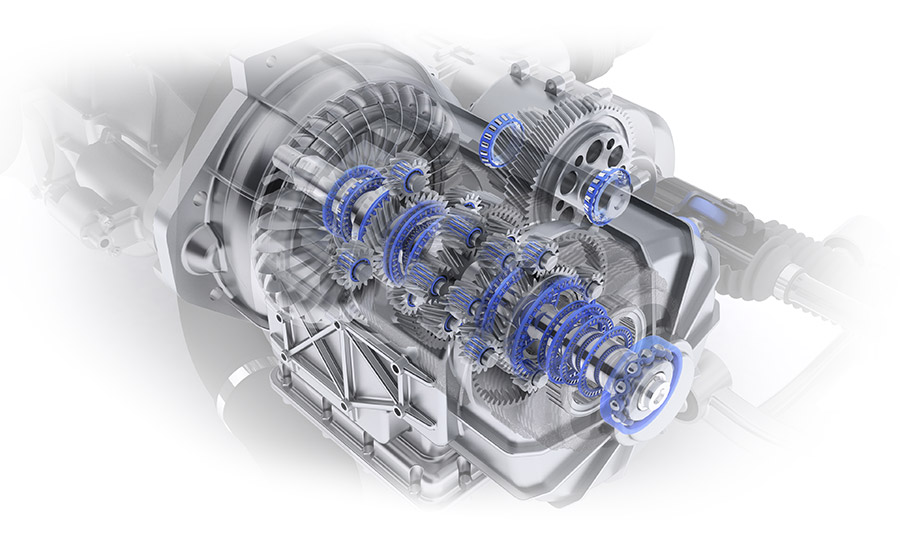

Automatic transmission/CVT

Low torque seal ring

It realizes low torque, low wear and minimal oil leak installing world's first V-shaped lubrication groove on the seal ring side.

Thrust washer

It is lighter weight and excellent in more space efficiency compared to thrust needle bearings. It is possible to design the oil grooves and other shapes by high flexible injection molding.

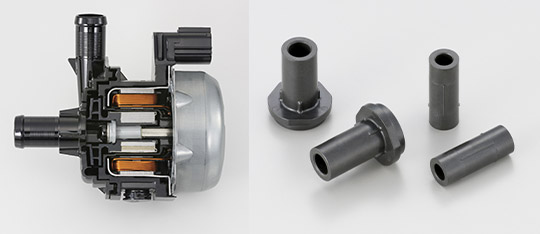

Electromechanical water pump

Plastic sliding bearing for rotor

It is made from engineering plastic with exellent heat resistance and lightweight. It also features outstanding friction and wear characteristics, and is usable under special environments such as in water.

Variable valve device

Oil seal

Flexible fluorine plastic is used for exellent sealing performance, heat resistance and low wear characteristics. A special filler also ensures minimal abrade to soft mating material.

Oil seal

It features excellent sealing performance, low friction characteristics and excellent wear resistance, even in oil. It enables low cost by forming multiple units with injection molding.

Compressor for air conditioning

Sliding seal

It is manufactured by injection molding for high precision with superior-flowing plastic. It is suited to compact, low vibration and high efficiency scroll type compressors, and has also excellent sealing performance.

Food machinery

※Please do not use BEAREE (plastic material) product for any application directly contacting with food.

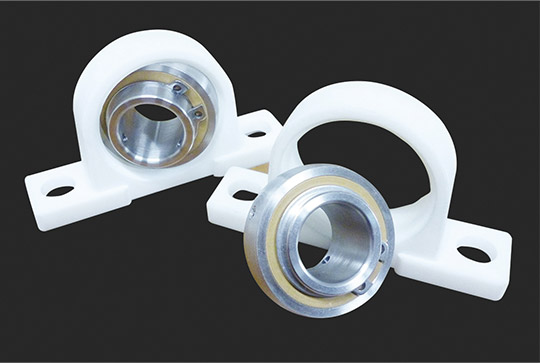

Plastic sliding bearing unit for rotor

As it has excellent water and chemical resistance, with greaseless operation, it is washable. It features easy installation, as the bearing can be aligned and it is integrated with housing. It can be used at high temperatures.

Plastic sliding bearing for rotor

It adopts sliding material combining engineering plastic or super engineering plastic with special fillers material to achieve excellent bearing performance.

Plastic cage for rotating table

It is made of water and chemical resistant material. In addition, the balls are designed for easy installation and removal. They can be removed when washing.

Plastic rolling bearing for rotor

It adopts material that is self-lubricating and with corrosion resistance for the inner/outer rings, balls and retainer for excellent water and chemical resistance. It can be used without additional lubrication.

Plastic sliding screw for lifting unit

It realizes lighter weight and lower noise by using a combination of BEAREE nuts and stainless steel (SUS304) rolling screw shafts. It can be used over a wide range of temperatures without additional lubrication, and it also features excellent corrosion resistance.

Machine tools

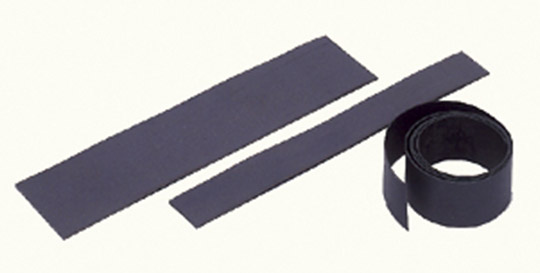

Sliding sheet for machine tool bed

It features excellent wear and creep resistance, and heat conductivity. It demonstrates good performance against stick slip, scoring and seizing. It realizes minimal loss of oil when starting, suited to repeated regular starting and stopping.

Compressor for air conditioning

Seal

It has excellent sealing performance for gas and oil, wear resistance, and low friction. It can be roughly classified into two types: injection molded and machined.

Piston ring

It is attached to the outer diameter of the piston and seals gas and oil while reciprocating.

It has excellent wear resistance and stable low friction characteristics, and can be used for sliding with soft mating material such as stainless steel (SUS).

Cup seal for reciprocal type

It is cup-shaped seal that easily follows the cylinder for better sealing of gas. It has excellent wear resistance and stable low friction characteristics even in lubricant free environment, and is not likely to abrade mating material. It can also be used under high surface pressure and speed conditions.

Aerospace

Cage of rolling bearing for turbo pump

It is machined using material with excellent friction and wear characteristics even at cryogenic temperatures. It can be used in bearings for liquid fuel turbo pumps.