Speckles and Discoloration

Speckles and Discoloration

|

Condition

Speckles

Discoloration

|

Cause

|

Solution

Speckles

Discoloration

|

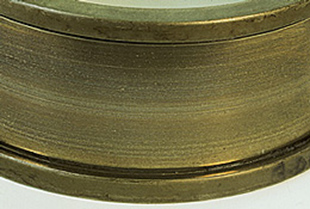

- Inner ring of double row tapered roller bearing (RCT bearing)

- Raceway surface is speckled

- The cause is electric pitting.

- Ball of deep groove ball bearing

- Speckled all over

- The cause is foreign objects and poor lubrication

- Outer ring of spherical roller bearing

- Partial oil deposition on raceway surface

- Spherical roller bearing

- Discoloration of inner and outer ring raceway surfaces

- The cause is deterioration of lubricant.