Cracking

Cracking

|

Condition

|

Cause

|

Solution

|

- Inner ring of spherical roller bearing

- Split of raceway surface in the axial direction

- The cause is excessive interference fit.

- Fracture of inner ring shown in Photo 3

- Originating point is observed at the middle of the left raceway surface.

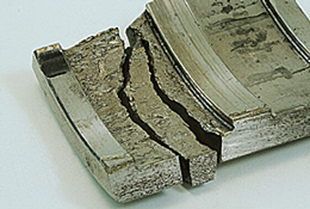

- Outer ring of four-row cylindrical roller bearing

- Split of raceway surface in the circumferential direction, originated from large flaking.

- The cause is large flaking.

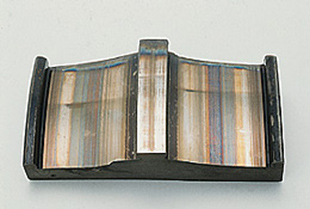

- Outer ring of angular contact ball bearing

- Split of raceway surface in the circumferential direction

- The cause is slipping of balls due to poor lubrication.