NTN Establishes Joint Venture in North America for the Pre Processes of Manufacturing Hub BearingsDecember 24, 2010

NTN Corporation (hereafter, NTN), Takao Kogyo Co., Ltd. (hereafter, Takao Kogyo) and Asahi Forge Corporation (hereafter, Asahi Forge) have decided to establish a joint venture in North America. The new company will carry out the integrated production of forging, turning, and heat-treatment as the pre processes of manufacturing 3rd generation hub bearings for automobiles.

1. Purpose of establishing the joint venture

In North America, with the recovery of demand for automobiles, particularly with an increase in new orders from American auto manufacturers, a significant rise in demand for hub bearings is anticipated. NTN has been steadily boosting its production capacity at its plants that manufacture finished hub bearings, but the company also needs to increase capacity in manufacturing pre processes.

At this time, NTN has decided to establish a new company jointly with Takao Kogyo and Asahi Forge, two companies that offer high level manufacturing technologies for integrated production of forging, turning, and heat-treatment.

The new company will use advanced manufacturing technologies to materialize production of smaller and lighter hub bearings, which will contribute to reduce automobile's fuel consumption and improve its ride. Also, integrating production of the pre processes will strengthen cost competitiveness and improve the profitability of products for small-sized automobiles.

In the future, the original manufacturing technologies that the new company establishes will be rolled out in Europe, China, and other regions. This will make the company's automotive driveline products highly competitive, including constant velocity joints, and establish a commanding position for the company in the global market.

2. Future plans

After the new company was established in December 2010, turning and heat treatment will start in June 2011. Forging is scheduled to begin in February 2012.

3.Outline of the joint venture

| (1) Company name | NTA PRECISION AXLE CORPORATION |

|---|---|

| (2) Line of business | Manufacture and sales of forged, turned and heat-treated parts |

| (3) Location | 795 Kimberly Drive, Carol Stream, Illinois U.S.A |

| (4) Registered capital | US$40 million (approx. 3.3 billion yen) |

| (5) Total investment | US$84 million (approx. 7 billion yen) |

| (6) Start of production | June 2011 (scheduled) |

| (7) Site area | Approx. 53,500 m² |

| (8) Total floor area | Approx. 20,000 m² |

| (9) Employees | Approx. 180 (scheduled) |

NTA PRECISION AXLE CORPORATION (image)

NTA PRECISION AXLE CORPORATION (image)

Reference

Outline of Takao Kogyo Co., Ltd.

| Establishment | October 1974 |

|---|---|

| Location | 3-13-2 Kusunoki, Yatomi-shi, Aichi Prefecture, Japan |

| Representative | Yutaka Shimomura, President |

| Employees | 550 (as of Oct. 1, 2010) |

| Sales | 8 billion yen (period ending July 2010) |

| Lines of business | Manufacture of automobile parts, precision machine parts and others |

| Affiliates | NTK PRECISION AXLE CORP. (60% NTN USA, 20% Takao Kogyo, others) |

Outline of Asahi Forge Corporation

| Establishment | October 1970 (founded January 1938) |

|---|---|

| Location | 4-16 Kaneda-cho, Kita-ku, Nagoya, Aichi Prefecture, Japan |

| Representative | Shigemitsu Asahi, President |

| Employees | 498 (as of May 31, 2010, consolidated) |

| Sales | 22 billion yen (period ending May 2010, consolidated) |

| Lines of business | Forged, heat-treated and machined parts for automobiles, bearings and construction machinery |

| Subsidiary | ASAHI FORGE OF AMERICA CORP. (60.6% Asahi Forge, 28.2% NTN USA, others) |

3rd Generation Hub Bearings

Hub bearings play a critical role in how a vehicle runs. They are attached to a vehicle's wheels and make it possible for the wheels to turn while bearing the weight of the chassis.

Hub bearings are becoming more and more unitized, with the number of parts decreasing from the first generation to the third (GEN3). This has resulted in lightweight, compact products that help to improve fuel consumption.

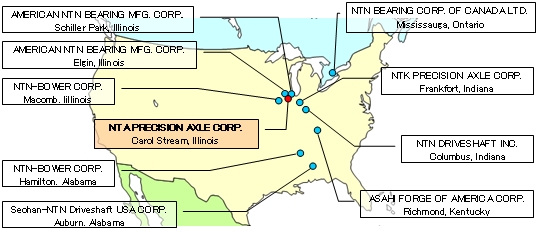

Production bases in North America