Development of “3D Microgeometry Measuring Machine”May 13, 2015

[Fastest speed in the compact, non-contact 3D measuring machine class]

NTN Corporation (hereafter, NTN) has developed the “3D Microgeometry Measuring Machine,” a compact, non-contact type 3D measuring instrument that is capable of measuring microscopic shapes of heights from a few µm to several 10µm (micrometer: 1µm is 1/1000 mm) at the fastest speed in the class, and displaying them in 3D.

In the microfabrication industry, control of surface characteristics and the finished dimensions of etching, precision machining and chemical liquid coating is essential, and efforts are being made to maintain product quality with inspections of external appearance during machining process and the finished product. Microfabrication technology requires an even greater level of quality and quicker inspection times than before due to miniaturization of circuit patterns in electronic parts and advances made in the medical field where a high level of reliability is required. Conventional 3D measuring instruments that are already available on the market require a long measuring time for verification purposes on manufacturing lines, resulting in issues related to practicality.

The newly developed “3D Microgeometry Measuring Machine” uses white light interferometry*1 and a high-speed camera for a level of precision with a 5nm (nanometer: 1nm is 1/1,000,000 mm) height detection resolution, allowing heights of 20µm to be measured in just 0.6 seconds, the fastest speed in its class. Heights can be measured with a high level of precision over a visible range of up to 1280µm × 960µm, which helps to reduce the time required for measurements.

NTN exhibits the developed product at the “BIOtech Japan 2015” to be held at Tokyo Big Sight from May 13 to 15. The product will be proposed to equipment manufacturers seeking to introduce NTN's microfabrication technology, and as an instrument that meets the needs of customers considering microscopic measuring instruments, and a series lineup will also be developed to further expand sales.

- A method that uses an interferometer and white light source to scan and detect the height direction with the interferometer at the point where the interference light strength is maximum.

Features

- Fastest measurement speed in its class: measures 20µm*2 heights in 0.6 seconds (height detection resolution of 5nm)

- Wide measurement range: measures with a visible range up to 1280µm × 960µm with high-precision

- The height measurement range can be increased up to a maximum 2000µm with optional specifications.

Applications

Measures microscopic surface shapes of metal and resin materials, and displays them in 3D.

Inquiries about this release

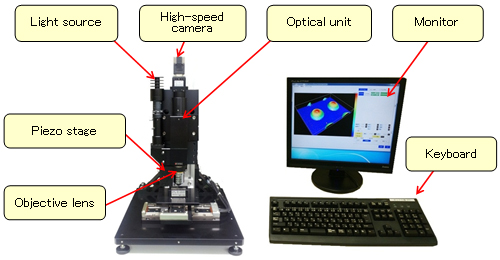

Product photo

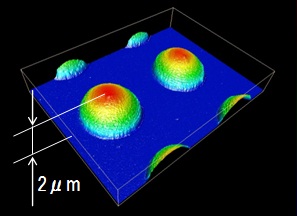

Example of applications (3D display)

1. Glass substrate surface applied at regular intervals with microscopic quantities of liquid*3

Measurement time: 0.6 seconds

Height measurement range: 20µm

Taken with 10× objective lens

(Field of view 320µm × 240µm)

- Samples made with NTN Microscopic Coting Applicator

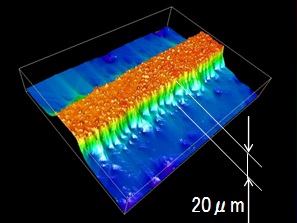

2. Commercial printed wiring board (after etching)

Measurement time: 0.9 seconds

Height measurement range: 30µm

Taken with 10× objective lens

(Field of view 320µm × 240µm)

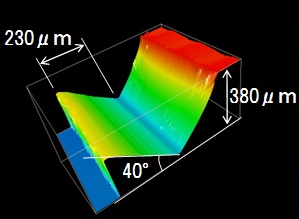

3. Machined part (material: stainless steel)

Measurement time: 15 seconds

Height measurement range: 500µm

Taken with 5× objective lens

(Field of view 640µm × 480µm)