Development of “Hollow Ball Screw Unit”March 12, 2013

[Thin and lightweight contributing to more compact and efficient electronically controlled CVT]

NTN Corporation (hereafter, NTN) has developed the thin and lightweight “Hollow Ball Screw Unit” designed for the electrification of various vehicle actuators.

Continuously Variable Transmissions (hereafter, CVT*1) have been increasingly used as vehicle transmissions in recent years, and feature oil-hydraulic pumps for the drive mechanism that adjusts the width of pulleys. Yet oil-hydraulic CVTs suffer from major energy loss during operation, and suffer from issues when trying to use more compact designs. Electronically controlled CVTs offer more precise gear control than oil-hydraulic CVTs and use slide screws for the drive mechanism, yet these slide screws consumed a large quantity of electricity due to their low thrust conversion efficiency.

The “Hollow Ball Screw Unit” developed by NTN uses a ball screw with a low rolling resistance to deliver double the thrust conversion efficiency, while the hollow screw shaft means they can be positioned along the same axis as the CVT pulley mechanism. Cutting out a screw groove and ball circulation groove from the hollow screw shaft at the same time eliminates the need for the separate “deflector” material that includes an S-shaped ball circulation groove installed on the nut side. The nut can be designed thinner and more lightweight without this “deflector”.

As a result of these improvements, using the “Hollow Ball Screw Unit” for the drive mechanism of electronically controlled CVT help to reduce energy and electronic losses due to pulley operation, and also allow CVTs to become more compact by using a layout on the same axis. It also contributes to a lighter weight and more fuel efficient operation of vehicles.

NTN will actively propose the Hollow Ball Screw and actuator units that use the Hollow Ball Screw as the electrification of CVTs and various actuators installed in vehicles and motorcycles is expected to increase into the future.

*1 “CVT”:Abbreviation of Continuously Variable Transmission. A transmission system where the pulley width is adjusted using a pulley drive mechanism for the optimal gear ratio to help improve fuel efficiency.

Features

- Rotational force thrust conversion efficiency of 70% or more (double that of sliding screws)

- Thin and light weight: thinner design by integrating the circulation groove with the screw shaft (20% lighter compared to deflector circulation methods)

Applications

Electronic actuator for pulley drives of electronically controlled belt-driven CVTs

Ball screw actuators for vehicles and motorcycles

Inquiries about this release

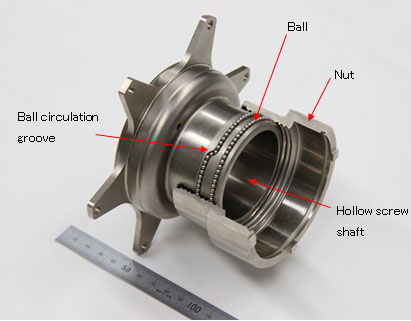

Product photo

Hollow Ball Screw Unit

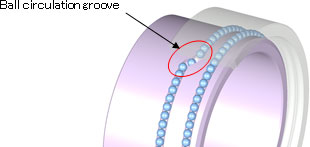

Zoom-in on the ball circulation groove (3D image)

*The adjacent ball circulation groove is located 180° out of phase

Reference

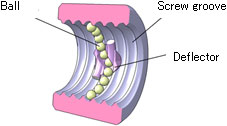

“Deflector” installed on conventional nuts (3D image)

*Including the ball circulation groove on the screw shaft eliminates the need for the “deflector”

installed on conventional nuts, resulting in a thinner, lighter weight design.