Development of “Hybrid PEEK Bearing”November 11, 2010

[Hybrid low-friction sliding bearing composed of sintered metal and PEEK series resin with excellent load capacity and heat dispersion properties]

NTN Corporation (hereafter NTN) has developed a “Hybrid PEEK Bearing” by blending resin and sintered metal with unique powder technologies. This new bearing has a unique range of properties including excellent load capacity, good heat dispersal, low friction and good wear resistance.

For sliding bearings used under high speed and high load conditions, fluorine series resin bushings are commonly utilized. This type of bushing (“MLE*1 type” Series) uses fluorine resin material which is then impregnated with sintered bronze powder and then curled into a cylindrical shape. A typical application for this bushing is an air conditioner compressor. Good anti-seizing and low wear properties are required for sliding bearings in this application because thin machine oil is typically used to lubricate compressors for reducing the environmental impact.

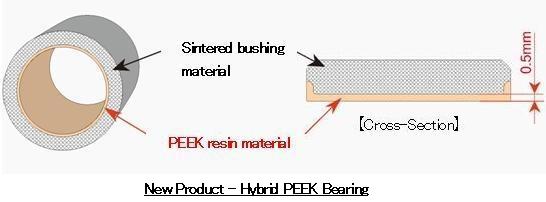

Due to this requirement, NTN improved the load capacity and heat dispersal properties by injection molding PEEK resin material (0.5 mm thickness) to the bore of a sintered metal bushing. The anti-seizing and friction/wear properties are superior compared to a standard fluorine resin bushing.

NTN will begin promoting “Hybrid PEEK Bearings” for room air conditioner compressors starting in November, with production expected to start in 2011.

NTN will promote this product to industrial machinery and automotive industries for transmission support bearings used in earth moving equipment and AT/CVT.

Features

- Excellent anti-seizing performance (500% improvement over standard product), ensuring good load capacity and good heat dispersal

(PEEK resin material (0.5mm thickness) is injection molded onto sintered bronze bushings) - Low friction and anti-wear properties are improved (Coefficient of friction reduced by 20%*2) and amount of wear halved*2), compared to standard product)

(Special material is dispensed in PEEK resin sliding material)

*1 Metal liner eco sliding bearing standard series,

*2 Typical measurement by NTN's testing

Inquiries about this release

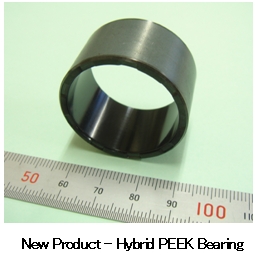

Product Photo

Example Cross-section

φ30×φ35×20 mm (Thickness of PEEK resin material: 0.5 mm)

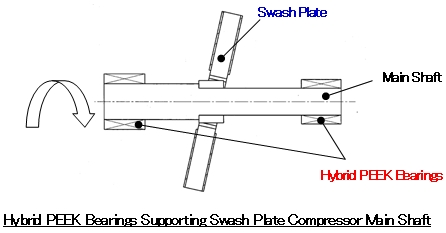

Typical Application Swash Plate Compressor Main Shaft Bearings