Development of “Self mounting type chain tensioner” for timing chainsOctober 13, 2010

[Lightweight and space saving design contributes to downsizing of engines and shortening of working time!]

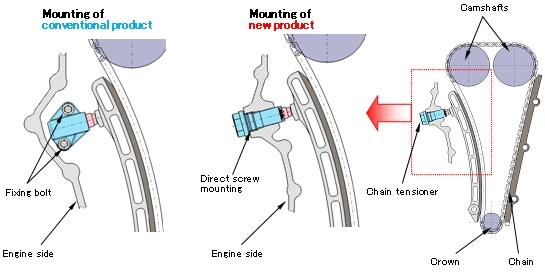

NTN Corporation (hereafter NTN) has been marketing “Chain tensioners” globally since 1998, to maintain proper tension of timing chains in the vehicles engine. This time, NTN has developed a “Self mounting type chain tensioner”, which is detachable from outside the timing chain cover and does not require bolts to attach it.

In recent years, the downsizing of automotive engines has progressed at an increased pace as fuel economy standards rise. Conventional engines require additional space for mounting chain tensioners inside timing chain covers as they are fitted to the engine block. Moreover, timing chain covers have to be removed at the time of maintenance and the removal and installation of chain tensioners can be troublesome.

This newly developed “Self mounting type chain tensioner” has a male thread on the outer diameter and enables simple mounting to the engine by tightening it into the female screw hole on the timing chain cover, therefore fixed bolt holes are not required. In addition, this product uses an aluminum die cast housing for weight savings.

Due to this design, there is a reduction of components; in addition, a compact design under the timing chain cover becomes possible, resulting in an improvement of fuel economy by weight reduction of the vehicle and a reduction of production and maintenance time.

Furthermore, this chain tensioner uses a “Buttress thread type no-back system” that enables it to constrain increases of chain amplitude due to the axial movement resistance of the buttress type thread. Accordingly, the function of the chain tensioner is improved and noise at engine start up is reduced.

NTN will be marketing this new product globally as an “Environmentally and human friendly product” contributing to fuel economy and easy maintenance.

Features

|

Approx. 50% weight reduction compared with the conventional product! |

|

|

||

Application

Timing chains for four wheel and two wheel vehicles

Inquiries about this release

Product photo

Examples of product mountings