Development of Interchangeable “Hydrodynamic Bearing Unit” with Rolling BearingAugust 19, 2010

[Replacing rolling bearing by hydrodynamic bearing with superior quietness is possible!]

NTN Corporation (hereafter NTN) has developed a hydrodynamic bearing unit, which is highly reliable, quiet, and interchangeable with a rolling bearing.

NTN has been manufacturing and marketing hydrodynamic BEARPHITE (Sintered metal hydrodynamic bearing) *1 as “Only one product” that is manufactured only by NTN. The product is widely used in applications such as HDD spindle motors and fun motors, due to its high reliability. In hydrodynamic bearings, the shaft rotates very quietly because the shaft and bearing are separated by an oil film in a non-contact condition. However, since its dimensions and operating conditions compared with rolling bearing are different, replacing a rolling bearing by a hydrodynamic bearing is constrained.

In response to market needs of producing a low noise bearing, NTN has developed an interchangeable hydrodynamic bearing of the same dimensions of a rolling bearing for applications with relatively small load and load fluctuation. Such applications include small ventilators and electric motors mounted on cars.

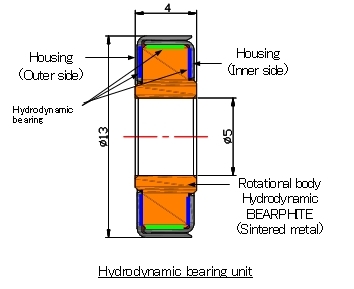

This new product uses hydrodynamic BEARPHITE for the bearing and maintains an equivalent torque to a rolling bearing while providing superior quietness. The simple design is contained within a housing unit in order to produce a bearing with the same external dimensions as a rolling bearing.

NTN is currently submitting samples for home use ventilators*2 and targeting to supply markets in fiscal year 2011. In addition, NTN will strive to make hydrodynamic bearings available for other applications requiring quietness by adding them to the series.

*1 “Hydrodynamic bearing unit” received the following awards.:

The 1st MONOZUKURI Japan Grand prize, The 1st MONOZUKURI Parts prize and Japan Society of Mechanical Engineers Tokai Branch Engineering prize.

*2 According to the revised Building Standards Law enforced on July 1. 2003, mechanical ventilation equipment is obligated to be installed as principle in all buildings with living rooms.

Therefore, demands for home use ventilators are increasing.

As they are also installed in living rooms and bed rooms, requirements for quietness are mounting.

Features

- Quietness and reliability of electric motors are improved with hydrodynamic bearings though non-contact support.

- Rotational torque equivalent to a rolling bearing is achieved.

- Rolling bearings can easily be replaced by a hydrodynamic bearing due to the bearings being identical in size.

Inquiries about this release

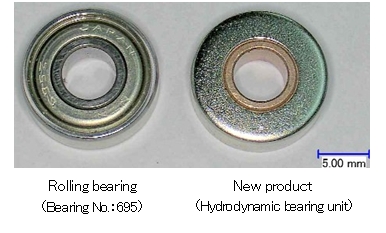

Product photo

Structure

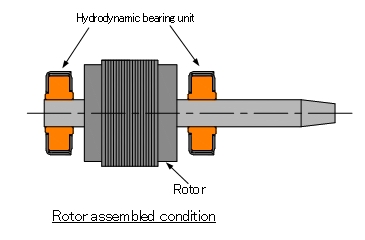

Example of application

Small motors such as for home use ventilators

Above structure is same sized hydrodynamic bearing unit (φ5×φ13×4mm) as rolling bearing (695).