Development of “Desktop Type Microscopic Coating Applicator”July 29, 2010

[Commercialization of the leading technology for liquid crystal manufacturing equipment as desktop devices for new applications such as biology.]

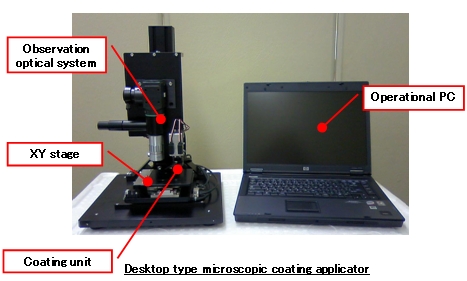

NTN Corporation (hereafter NTN) has developed a “Desktop type microscopic coating applicator” (hereafter applicator), which is capable of microscopically coating a dot about 0.01mm in diameter with an ultra small droplet on the order of a few pl (picoliter) * with a positional accuracy of 0.001mm.

NTN has the world sales record for color filter repair equipment in the field of flat panel display (FPD) repair equipment for devices such as a liquid crystal TV. This applicator is aimed at development for applications such as R&D in the field of advanced technologies. Its purpose is to provide a “Repair ink coating function” (hereafter coating function) of the color filter repair equipment as a desktop type machine.

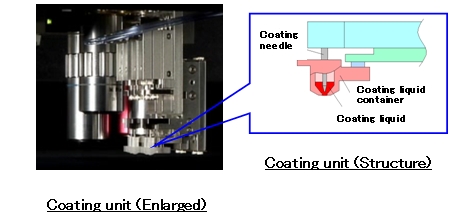

The piece of equipment known as a dispenser is a device which coats microscopic droplets. However, it is not suitable for controlling very small droplets on the order of a few pl (picoliter). Furthermore, as the nozzle diameter is required to be ultra fine to coat extra small microscopic droplets, there is a fear that the droplets will get clogged in the nozzle. To solve this problem, this applicator uses an unique coating method. The droplet is copied/coated by having a needle (coating needle) on the end of which a microscopic droplet is attached by contacting the object. Therefore, the volume of the droplet can be controlled precisely and the nozzle never gets clogged. In addition, two sets of coating liquid containers and coating needles are furnished as a standard specification. It is also possible to continuously coat by selecting two kinds of liquids according to the application.

This applicator was developed with the intention that its coating function would be used for R&D or at a prototype/small volume production site. Easy installation is made possible by the compact desktop size. The equipment is also very user-friendly as the microscopic droplet coating can be easily conducted by selecting the coating position on the PC screen with the mouse.

* pl (picoliter) : Trillionth liter

Features

- “Repair ink coating function” (No.1 record in the sales of liquid crystal repair equipment)is installed.

- Coating of an ultra microscopic amount of liquid (such as a reagent) on the order of a few pl (picoliter) is possible.

- Clogging of the nozzle does not occur thanks to the unique coating method using a coating needle.

- Installation and handling of equipment are easy thanks to the desktop size.

- Installation area for the main body is about 30cm2. Operating voltage is AC100V.

- Microscopic coating is conducted with easy mouse operation.

Applications

For R&D or prototype/small volume production

- R&D of cell culture, biology and new medicine…Divided injection of extra microscopic amount of sample (reagents, etc.)

- Prototype production development of electronic circuit (integrated circuit)…Wiring change/repair with conductive paste coating

- Assembly work of micro parts such as micro machine…Coating of adhesive agents

- Development of liquid material…Property evaluation of conductive paste, color resistance, etc.

Inquiries about this release

Product photo