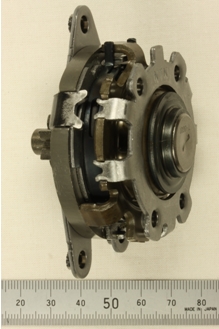

Development of “Thin Type Torque Diode” for Automotive Seat LiftersJune 14, 2010

Contribution to simplify structure and reduce weight of seats !

NTN Corporation (hereafter NTN) has been supplying Torque Diodes for automotive seat lifters (clutch to move seat up and down) that had been jointly developed with SHIROKI Corporation since 2002. NTN and SHIROKI Corporation have now developed a “Thin type Torque Diode” which is not only thinner but also has higher strength than the conventional type. This will assist suppliers in reducing the overall weight of a seat assembly by simplifying its framework.

Automotive seat lifters using NTN's conventional Torque Diodes were welcomed into the market because of features such as (1) the ability to raise and lower the seat with very little force being applied to the lever located between the seat and the door: as compared to the dial type seat lifter which requires the user to rotate a wheel that is located in the same position. (2) reduced noise of a non-step type adjustment system. At the present time, NTN's Torque Diodes are dominating the domestic market.

A target area where automotive suppliers can help with improvements of both fuel consumption and operational performance is through the development of light and simple seat framework; an area currently progressing in Japan and overseas. To help achieve the abovementioned target, improvements in performance of a Torque Diode for seat lifters is required.

The “Thin type Torque Diode” that has been developed is both thinner than the conventional type and has an increase of static torque capacity through the improvement of component part design. This advanced product allows for improvements in the automotive seat as described below:

- Increase the gap between the door and the seat lifter lever by making the Torque Diode thinner, allowing the user more room to grasp the handle.

- Seat retention force (static torque capacity) at any specific position has increased; with the strength improvements related to component part design, the Torque Diode is capable of supporting a greater amount of mass.

- When the load transfer system was simplified by increasing retention force (static torque capacity), it was possible to reduce the overall weight of the seat assembly.

NTN will aggressively strive to market the “Thin type Torque Diode” with the above mentioned improvements in features for the next generation of seat lifters.

Features

(Compared with NTN's conventional product)

| (1) Width |

Reduced by 16 % |

|---|---|

| (2) Static position retention force |

1.6 times |

Application

Position retention unit for automotive seat lifters (clutch to move seat up and down)

Inquiries about this release

Thin type Torque Diode appearance photo

Applied position of product