Development of “High Speed Angular Ball Bearing New 9 Series (HSE9-U)” for Machine Tool Main SpindlesMay 14, 2010

[Improving rigidity and permissible axial load, maintaining high loading capacity by optimized internal design!]

NTN Corporation (hereafter NTN) has reviewed the thin wall ‘High speed angular ball bearing 9 series (bearing type: HSE9)’ *1) for machine tool main spindles and developed “High speed angular ball bearing New 9 series (HSE9-U)” with enhanced loading capacity and bearing rigidity, while maintaining high speed performance. The new 9 Series design will be added to the ULTAGE*2) line-up of machine tool bearings.

The development of consolidated process machine models is a recent trend in the machine tool industry, driving main spindle requirements towards high speed performance and high rigidity,, improved cutting performance and high precision . Additionally compact size and multi-function performance of machine tools are demanded. For the main spindle system in particular, steady rigidity under varied processing conditions and down-sizing are demanded.

For these needs, the 9 series having a thin wall bearing cross-section offers a possible approach to down-sizing through the enhancement of main shaft rigidity by increasing the shaft diameter while reducing the bearing outer diameter.

Furthermore, in addition to multi-process capability, improved life, higher load capacity and rigidity as well as improved rigidity during low-speed operation are demanded for the main shaft bearings.

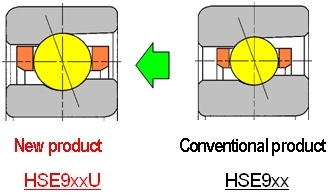

In response, NTN has reviewed the bearing internal design of the conventional ‘High speed angular ball bearing 9 series (HSE9)’ and developed the new 9 series with improved load capacity and rigidity. This approach enables higher permissible axial loading and the application of heavy loads during tool changes. Moreover, high rigidity during low speed operation is ensured and application over a wide range of processing conditions becomes possible.

Mounting dimensions are the same as for the conventional ‘High speed angular ball bearing 9 series’ and completely interchangeable. NTN has already started to approach new main spindle development at our customers with this new series, and will begin switching over from the conventional products and promoting global sales including newly developing countries and growing markets.

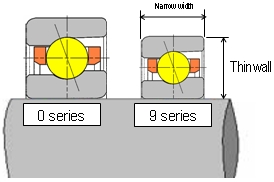

*1 Indicates dimension series of bearing. Angular ball bearings of 0 and 9 diameter series are mainly used for the machine tool main spindles.

Outer diameter and width dimensions of 9 series are smaller than those of 0 series, and bearing cross sectional area of the 9-seies is about 50% of the 0-series for a given bore size.

*2 ULTAGE is a coined word combining ‘Ultimate’ and ‘Stage’ and is the brand name for NTN's new generation bearing series, which are at the world's highest level.

Features

| (1) Improved Life |

Load rating increased by 50% (Life rating: 3 times conventional product) |

|---|---|

| (2) Improved Load Capacity |

Permissible axial load improved by 20% |

| (3) Improved bearing rigidity |

Radial rigidity and axial rigidity 1.5 times higher (Compared with conventional product) |

Application

Machine tool main spindles (Machining center, combined processing machine etc.)

Product photo

Structure

1. Cross-section surface comparison of angular ball bearing 0 and 9 series

2. Cross-section surface configuration of conventional product and new product