Development of “Multi Axis Load Sensor Integrated Hub Bearing”March 17, 2010

World's Highest Level of Accuracy, Contributing to the Enhancement of Advanced Vehicle Safety Control

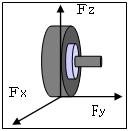

NTN Corporation (hereafter NTN) has developed a “Multi axis load sensor integrated hub bearing”. The sensor is capable of detecting a load in all three directions (Fx, Fy, Fz) *1 , and controls vehicle handling with the world's highest level of accuracy.

The vehicle is equipped with a control system to improve safety and make driving easier. In the system, signals from the acceleration sensor, Yaw rate sensor*2 and ABS sensor*3 are integrated to establish the vehicle's driving conditions. Conventional sensors start to control the vehicle after handling becomes unstable, however, slow response performance can cause issues. To improve vehicle control, it is useful to detect friction force between the tire and road surface to accurately understand the contact condition. In addition, it is important to detect real time road surface signals. NTN developed the "Load sensor integrated hub bearing" with the capability of detecting loading in three directions in 2007, at the request of various customers.

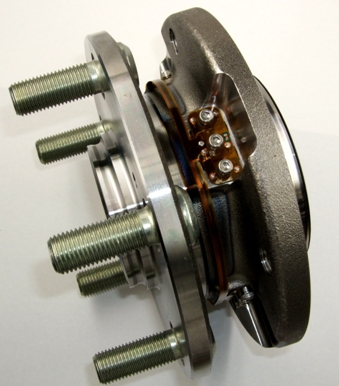

This latest product detects driving and braking force (Fx), vertical direction force (Fz), in addition to cornering force (Fy) as mentioned above. A strain element detection sensor is mounted on the bearing outer ring, which is a fixed component. The outer ring of a hub bearing produces very little deformation when loaded, and deformation varies depending on direction of the load. Very small deformations in each of the three directions are detected by sensors at four positions (top, bottom, left and right) and calculated with the world's highest level accuracy of ± 5% FS (full scale). The algorithm used to compute these signals was developed jointly between NTN and SNR, and is one example of the synergy between the two joint companies. A thermal sensor is integrated within the sensor to eliminate any thermal effect. Load detection under stationary vehicle conditions is also possible as the sensor detects outer ring deformations even in a static scenario.

By detecting three directional loads with this new product, the force transmitted to the road surface through the tire as well as direction can be detected. Accordingly, determination of road condition is improved, and accurate vehicle control becomes possible. Loading is detected closer to the tire, and quicker detection of the road surface condition change in relation to the vehicle becomes possible. It is typically said that about 0.2 seconds is needed for response, whereas response time for this new product is only about 0.05 seconds. This difference of 0.15 seconds is equivalent to a distance of 4.2m at a driving speed of 100km/h. Therefore, prompt prediction of road condition changes and resultant improvements of vehicle control and stabilization become possible with the addition of this component to the vehicle.

NTN will globally market this product that contributes to the enhancement of vehicle safety control.

*1 Three direction load

Fx : Driving force, Braking force

Fy : Cornering force

Fz : Vertical direction force

*2 Yaw rate sensor: Angular velocity detection in the turning direction of the vehicle

*3 ABS: Anti-lock Break System (Tire lock prevention unit)

Features

By integration of a strain element sensor into hub bearing, advanced vehicle control with the world's highest level of accuracy is possible.

- High accuracy (± 5% FS) detection of three axis loads (Fx, Fy, Fz)

⇒ Accurate vehicle control by highly accurate determination of road surface conditions - Measurement of conditions closer to the tire (Hub bearing)

⇒ Quick detection of road surface condition changes

Response time: Conventional 0.2 second ⇒ 0.05 second

(Equivalent to 4.2m distance at a speed of 100km/h) - Load detection under stationary vehicle conditions is possible.

Application

Hub bearings for passenger cars

Appearance photo of multi axis load sensor integrated hub bearing