Development and commercialization of the ULTAGE Series ‘Next generation deep groove ball bearing for high-speed servomotors’March 12, 2010

[Greased and sealed-type ball bearing for improved reliability]

NTN Corporation (hereafter NTN) has developed the ‘Next generation deep groove ball bearing for high-speed servomotors.’ Commercialized as the ‘ULTAGE Series*1’, this bearing is a greased and sealed-type ball bearing with the capacity to respond to a dmn value*2 of one million, for FA systems such as machine tool, robot, transfer equipment, etc.

In recent years, performance (high speed, high output, and long life) of servomotors for industrial machinery, as well as FA equipments such as machine tool main spindles, has been improving. In today's marketplace, high quality and high reliability are of particular importance.

In 2004, NTN developed the ‘Next generation deep groove ball bearing for high-speed servomotors’. In response to the recent requirements, NTN has further improved its life and endurance performance with the development of the ‘ULTAGE Series’.

Waved-type pressed steel cages are generally used for ball bearings but when they are used under high-speed conditions, wear occurs on the pocket surfaces due to collision with balls. For this reason, plastic cages are used in place of waved-type pressed steel cages. In particular, for applications of high speed and urgent acceleration and deceleration operation (ON-OFF actuation) such as servomotors, NTN has been using a cage that combines two plastic parts to increase the rigidity of the cage (High-speed plastic cage developed in 2004).

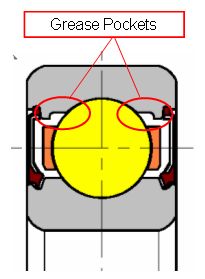

Aiming to further enhance the reliability of servomotor bearings, NTN has improved the urgent acceleration and deceleration durability performance by more than two times compared with the conventional product. In order to make this improvement, NTN focused on the cage behavior caused by the advance and delay in the movement of the balls. The cage pocket design was improved and grease pockets were provided on the outer ring in order to increase the grease lubrication life. NTN launched this new product as the ‘ULTAGE Series’ bearing earlier this year.

*1 ULTAGE is a coined word combining ‘Ultimate’ and ‘Stage’, to designate the world's highest level (NTN's new generation bearing series).

*2 dmn value = dm (rolling element pitch circle diameter in mm) x n (rotational speed in rpm)

Features

- High speed, High reliability (Improving urgent acceleration and deceleration durability performance)

Stabilization of cage behavior under high acceleration and deceleration operation at a dmn value of one million

⇒ More than two times the durability performance of conventional product under high acceleration and deceleration - Longer grease lubrication life

Providing grease pockets on outer ring ensures a longer grease lubrication life

⇒ The grease lubrication life of bearings with grease pockets was seven times that of the conventional product (no grease pockets) - Low noise

Low noise performance is maintained using a high-speed plastic cage

⇒ High-speed plastic cage showed a reduction of 3 dB-A when compared to the conventional product (waved-type pressed steel cage)

Available bearings

6209, 6210, 6308, 6310, 6312 (Bearing bore diameter φ40~60: 5 bearings)

Inquiries about this release

Product Appearance

6308(φ40×φ90×23)

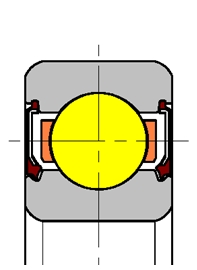

Cross Section Structure

![]()

New Type(ULTAGE)

Conventional Type