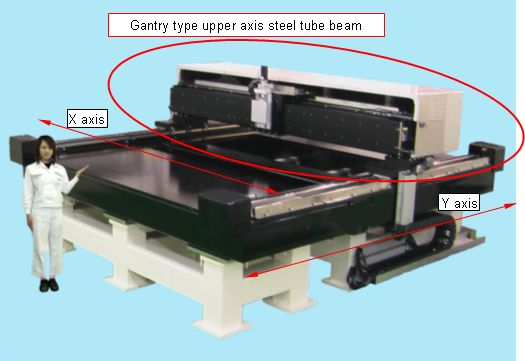

Development of “High Performance Large Type Gantry XY Table”March 12, 2010

[Large type precision positioning drive unit attains light weight, high rigidity, and low cost]

NTN Corporation (hereafter NTN) has developed a new 'High performance large type XY gantry table'. Realizing light weight, high rigidity and low cost, this product is a gantry type high precision positioning XY table targeted towards manufacturing facilities producing or inspecting large-scale solar energy panels or flat panel displays.

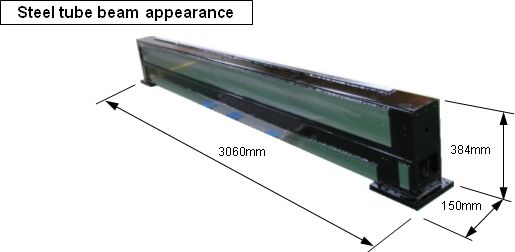

Responding to the trend by panel manufacturers towards increased work size (such as liquid crystal glass substrates), manufacturing and inspection equipment sizes are also increasing for improved production efficiency. In addition, the market is demanding improved equipment performance in the areas of high precision and high speed to achieve increased processing throughput*1, for which light weight, highly rigid and highly precise components are absolutely imperative. NTN has achieved both light weight and high rigidity of the upper axis beam by using thin-sectioned square steel tubing optimized for high stiffness by structural analysis, resulting in reduced inertia during long strokes.

For the newly developed high performance gantry table, a 60% mass ratio and 120% rigidity ratio were achieved in comparison to the conventional beam. This achievement can contribute to shortened settling time of a sudden deceleration stop after high speed traveling, as well as enabling reduced size and output of the linear drive motor. Also, square steel tubing is superior in availability and workability compared with special high performance materials such as CFRP*2, ensuring highly accurate material may be procured in a flexible manner and at a low cost.

In addition to the newly developed beam, NTN also applied design optimizations to the lower axis base and drive train, resulting in a large size precision positioning drive unit with superior cost performance.

*1 Throughput: Amount of works that plant and machinery etc. can handle in a limited time.

*2 CFRP: Carbon-Fiber Reinforced Plastic

Features Function and performance responding to production equipment and inspection equipment for large type glass substrates etc. are realized.

| (1) Light weight |

60% compared with conventional type (Upper axis beam) |

|---|---|

| (2) High rigidity |

120% compared with conventional type (Upper axis beam) |

| (3) Low cost |

80% compared with conventional type (XY table total cost) |

| (4) Table traveling speed |

120% compared with conventional type (Max. speed: 2,000mm/s) |

Inquiries about this release

Photo of whole equipment

Upper axis steel tube beam and features

Features

| (1) Light weight |

Mass ratio 60% |

|---|---|

| (2) High rigidity |

Rigidity ratio 120% |

| (3) Low cost |

Equipment total cost 80% compared with conventional type

|