Development of World's smallest bore hydrodynamic bearingMarch 4, 2010

[Achieving the world's smallest bore hydrodynamic bearing with hydrodynamic grooves formed by special technology.]

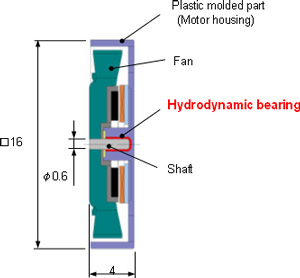

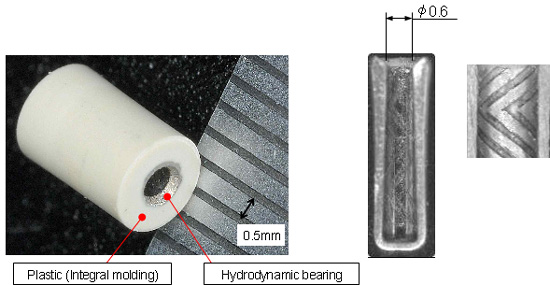

NTN Corporation (hereafter NTN) has developed and commercialized the world's smallest bore hydrodynamic bearing for a shaft diameter of 0.6 mm by combining electrocasting* and plastic injection molding technologies.

NTN is currently manufacturing hydrodynamic Beaphites, and those hydrodynamic grooves are formed on the bore diameter surfaces of oil impregnated sintered bearings. Because of the high reliability, sales of those bearings are increasing for applications such as HDD spindle motors, fan motors, etc.

Demands are expected to increase for small fan motors used in mobile equipment. These applications require further down sizing (shaft diameter: 1 mm or less) as well as quieter sound quality and higher reliability.

In response to these needs, NTN has developed the world's smallest bore hydrodynamic bearing. The bearing has hydrodynamic grooves formed on the bearing bore surface by utilizing the precision transcriptional performance of electrocasting*, a kind of electroplating. Because injection molding is applied during the production of this bearing, down sizing of the bearing and the equipment, as well as integration with its surrounding plastic parts is possible. Furthermore, reduction of the number of components and the required number of assembly workers are also assured. NTN has already started to offer the prototypes to fan motor manufacturers and is expecting the adoption for their productions during this year. The manufacturing method used for the production of this bearing makes further down sizing possible and NTN will be working to develop a bearing for a shaft diameter of 0.3 mm in the future.

*: Precision duplication method that electrodeposits metal on the electrode surface and duplicates product with the same configuration as the original product.

Features

| (1) World's smallest bore hydrodynamic bearing |

Hydrodynamic bearing for 0.6 mm shaft diameter using precision duplication performance of electrocasting |

|---|---|

| (2) Integration with plastic parts is possible |

Integral molding is made possible by plastic injection molding |

| (3) Quieter sound quality and high reliability |

Rotational shaft is supported by hydrodynamic effect |

Inquiries about this release

Photo

Application Small fan motor for mobile equipment etc.

The shape of the fan motor housing, illustrated below, as well as the sleeve shown in the product photo are capable of being molded. The integral molding of the plastic molded part with the surrounding plastic parts allows for the reduction of the number of parts as well as the reduction of the required number of assembly workers.