Tapered Roller Bearing Optimum Design Program for TransmissionFebruary 5, 2010

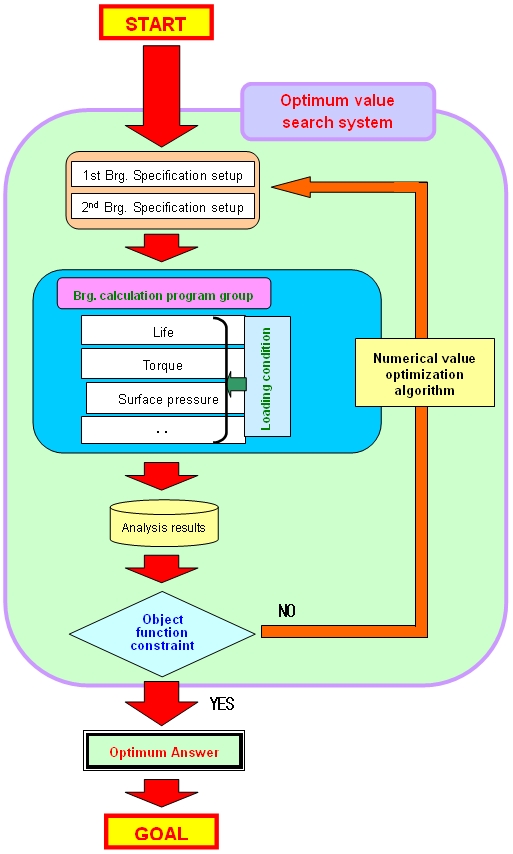

In order to contribute to torque reduction, down sizing and mass reduction of transmissions, NTN Corporation (hereafter NTN) has developed a program which enables to design optimum tapered roller bearings in high speed and automated manner, responding to various purposes such as torque reduction, down sizing, mass reduction etc. as well as satisfying required properties on bearing life, rigidity and safety ratio etc..

Car manufacturers are working to improve to fuel economy for the fuel efficiency regulation revision scheduled in 2015. NTN has been contributing to the improvement of fuel economy for vehicles by means of ‘High rigidity and ultra low toque tapered roller bearing’. However, further torque reduction is requested by car manufacturers. Two pieces of tapered roller bearings are generally used for one shaft of transmission or differential gear. Many design specifications are involved in a tapered roller bearing, and the optimum design even for one bearing is a hard task. When two tapered roller bearings are used, the induced axial load due to modified specification of the one bearing effects to the other bearing. Accordingly, number of specifications and mutual effect of two bearings were bottle necks for the optimum design.

The new program enables to automatically design specifications, leading to the lowest torque, the smallest size or lightest weight among many bearing specifications, taking mutual effect of two pieces of bearings into account, as well as satisfying operating conditions (load, rotational speed, operating ration at each speed range etc.) provided from customers. By use of this program, the design study time is drastically shortened up to 1/10 compared with a conventional design.

Thanks to this program, not only improvement of product performances such as torque reduction, down sizing and mass reduction, but drastic shortening of development time is made possible. Numerical optimization method of this program is widely applicable to automotive or industrial machinery as well as transmission and differential gear.

Features

| (1) Tapered roller bearing study with optimum design specifications |

|

|---|---|

| (2) Automated design of tapered roller bearing |

|

Application

Tapered roller bearings for automotive transmissions and differential gears

Inquiries about this release

Fig.1 Optimum design program image

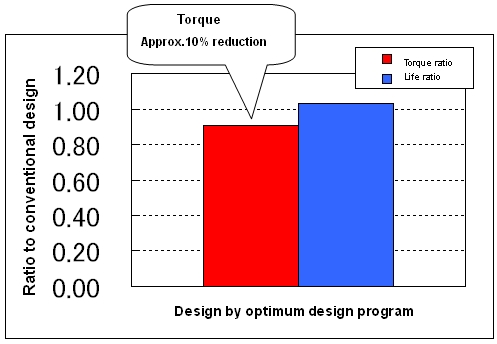

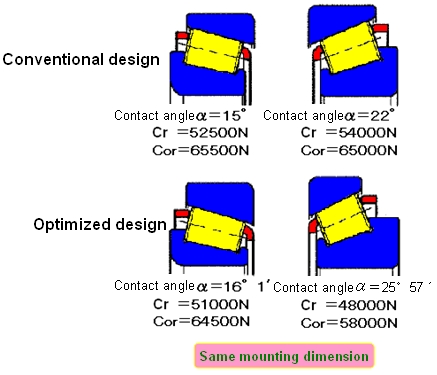

Fig.2 Example of torque reduction study