Development of “Low Friction Hub Bearing”January 18, 2010

[Friction of hub bearing during straight driving conditions reduced up to 40% resulting in fuel efficiency gains upwards of 1.5% (responding to energy savings)]

Contributing to fuel economy improvement for vehicles, and in an effort to help the environment, NTN Corporation (hereafter NTN) has developed a “Low Friction Hub Bearing” that reduces friction in straight driving conditions (the highest operating frequency) by up to 40%. With this product technology, fuel economy improvements of up to 1.5% are expected.

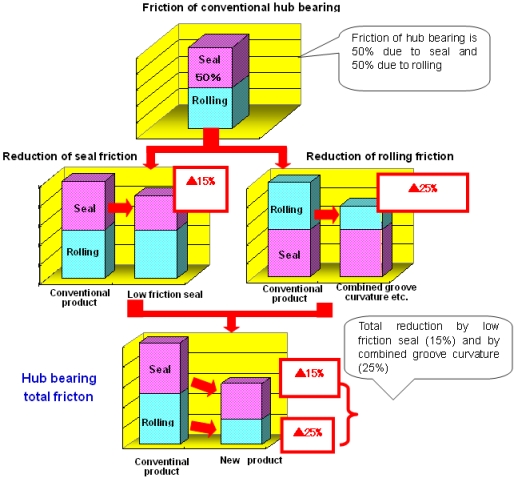

In recent years, environmental issues such as global warming have attracting much attention, and for hub bearings, weight reduction and lower friction losses are required to improve fuel efficiency of cars. NTN developed a low friction seal, which reduced sliding friction of the hub bearing seal by approx.15% (sliding friction of the seal represents about a half of the total friction in a hub bearing) that was offered it to the market. However, the market requested further reductions in friction.

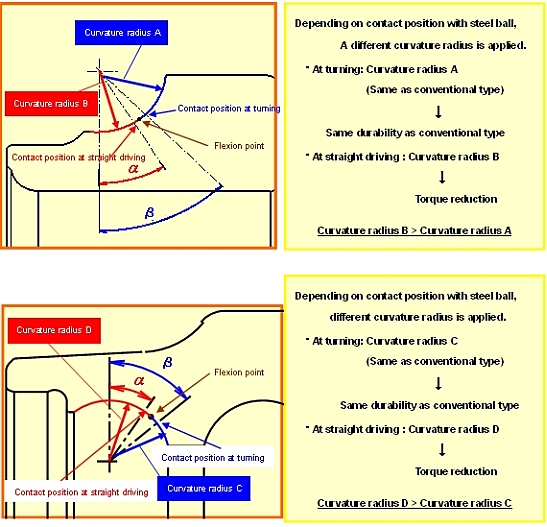

This new product decreases rolling friction during straight driving of the vehicle by improving the raceway configuration of the hub bearing in conjunction with the low friction seals mentioned above. As a theory, when the raceway groove curvature radius is made larger, bearing rolling friction is decreased. However, when the curvature radius is made larger, contact surface pressure between the steel ball and raceway surface, while loaded, becomes higher, and the durability of the bearing is lowered; consequently it is difficult to make the curvature radius larger.

For this new product, on the basis that the contact position of the steel ball with the raceway changes depending on the load acting on the hub bearing, a combined curvature was adopted - the groove radius at the contact position for straight driving was made larger than the conventional design, and the groove radius at a contact point at the time of turning (where the effect on bearing durability is significant) was made the same as for a conventional design. By doing this, the same durability as the conventional product was achieved as was reduced rolling friction at the time of straight driving of the vehicle. At the same time, the pre-load range was made smaller than that of the conventional product, further reducing friction. Through these design modifications, rolling friction of the hub bearing was reduced by approx. 25% and together with the use of low friction seals, hub bearing friction for straight driving conditions was reduced up to 40%.

Environmental awareness is NTN's biggest concern and NTN is aiming to reduce environmental impacts and create an environmentally friendly society. NTN will be marketing this “Low friction hub bearing” globally.

Features

| (1) | Use of combined groove curvature ⇒ Reduction of rolling friction and the same bearing durability as conventional type |

|---|---|

| (2) | Reduction of initial preload range ⇒ Reduction of rolling friction |

| (3) | Use of low friction seal |

Explanation

(1)Combined groove curvature of bearing raceway |

(2)Breakdown of low friction |

(3)Appearance photo of low friction hub bearing |

Application

Automotive hub bearing