Development of a “Wide-Range High-Resolution Small Sensor Integrated Hub Bearing”January 5, 2010

[responding to a wide range of rotation contributing to enhanced vehicle control]

NTN Corporation (hereafter NTN), jointly with SNR (France), has developed a “Hub bearing integrated with a wide-range high-resolution rotary sensor”, to enhance vehicle control.

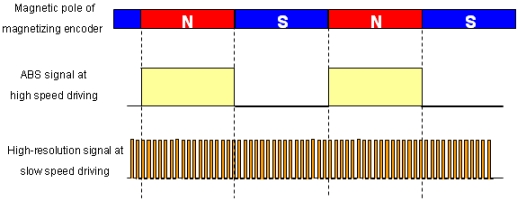

Wheel rotary sensors enhancing vehicle controls such as speed detection, ABS*1, and ESC*2 are integrated in most wheel bearings (hub bearings). The wheel rotary sensor detects magnetic pole changes of the magnetic encoder (rotational side) by the sensor (fixed side), which is used as wheel rotational signals for vehicle control. North and South poles of the encoder are circumferentially -magnetized alternately with equal spacing.

By making the rotational signal finer (enhancing resolution), very small movement of the vehicle is detectable, and better control of the vehicle becomes possible. In 2007, NTN developed a “Hub bearing with a high-resolution rotary sensor”, which integrated a magnetic sensor with high resolution - up to 40 times better resolution using a conventional magnetic encoder. However, the need for large amounts of data processing capacity at high speed driving (i.e. number of output pulses per unit time at high speed driving decreased, maintaining high resolution at slow speed) had been an issue.

This time, NTN has developed a “Wide-range high-resolution small sensor integrated hub bearing” enabling two kinds of output signals; ABS and high-resolution signals. This product can detect the wheel rotational speed at low and medium driving speed range with accuracy 40 times better than the conventional product. Therefore, a very small movement of the vehicle (1 mm with a standard vehicle) can be detected and control of vehicle braking force with optimum timing becomes possible. At high-speed range, the burden of data processing capacity becomes smaller by use of ABS signals.

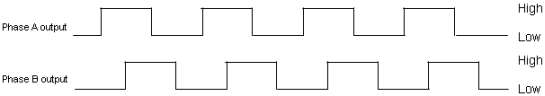

The high-resolution signal of the product outputs two kinds of pulses (phase A & B pulses) to detect rotational direction. By checking the output condition of these pulses, detection of forward and reverse movements of the vehicle is possible. This is believed needed for detection of backward motion when starting to move on a slope, and for vehicle control at the time of parking. In addition, design flexibility was improved by use of a smaller IC (integral circuit) for the sensor, and downsizing of the product became possible.

NTN will be globally marketing this product in an effort to contribute to the enhancement of vehicle control.

*1 ABS: Anti-lock break system (Tire locking prevention unit)

*2 ESC: Electronic stability control (Vehicle stability control unit)

Features

| (1) | Simultaneous output of high resolution signal (40 times compared with conventional type) and ABS signal (Magnetic encoder is the same as conventional one) | |

| Low and medium speed range : | High resolution signal⇒Detection of very small movement of vehicle is possible (1/40 compared with conventional type: 1mm movement of vehicle is detectable) |

|

| High speed range : ABS signal⇒Small burden to data processing capacity | ||

| (2) | Rotational direction is detectable by phase A & B pulse outputs. ⇒Recognition of forward/reverse movements of vehicle is possible |

|

| (3) | Smaller IC compared with conventional type ⇒Down sizing of hub bearing |

|

Explanation

| (1) High resolution signal (40 times greater than conventional type) and ABS signal |

|

| (2) Detection of rotational direction by phase A & B pulse |

With this product, two signals with different phase (phase A, B) outputs is created as shown above. When the bearing rotates in a certain direction, the signal outputs from left to right as the figure above shows. Phase B changes from low to high after phase A changes from low to high. When the rotational direction inverts, phase A changes from low to high after phase B changes from low to high because signal now goes from right to left on the above outputs. By judging the order of the change, the rotational direction of bearing, i.e. forward/reverse movement of vehicle can be determined. |

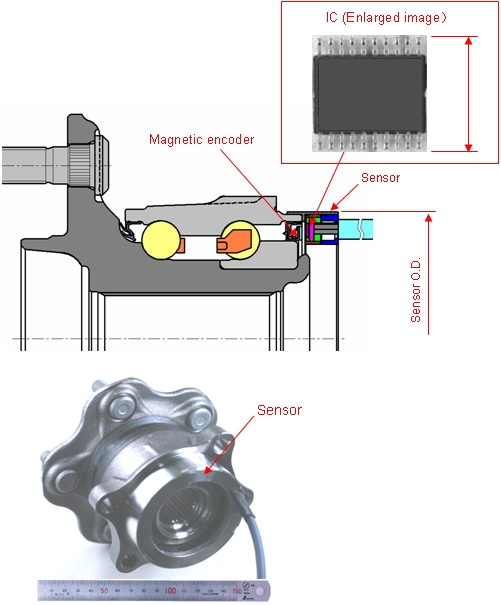

| (3) Down sized product by use of smaller IC |

|

IC is integrated at opposite position to magnetic encoder of sensor. By downsizing the IC (width: approx. 20% less), reduction of outer diameter of hub bearing is possible.  |

Application

Automotive hub bearing