April 12, 2007

Development of New High Speed Bearing Unit

(New RCT® Bearing) For Railroad Journal Applications

[Bearing maintenance interval period has been doubled]

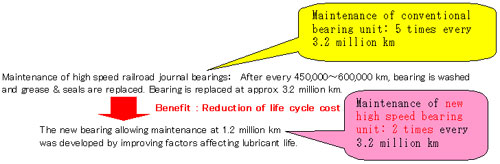

NTN corporation (hereafter NTN) developed a new high speed bearing unit (New RCT Bearing) for railroad journal applications. The sealed double row tapered roller bearing has a maintenance interval period which is double that of conventional product.

Recently railroads have been looked upon in a new and favorable light. They are mass transportation vehicles that are environmentally friendly and consume low energy. Bearing demand for railroad applications is increasing substantially. In particular, demand is high in China where the railroad network is aggressively expanding in response to economic growth; and in the EC market where higher speed railroad networks are being promoted along with European integration.

All bearings for railroad applications are considered key control components and require high reliability. At the same time, railroad companies are requiring cost reduction and extended maintenance intervals while maintaining high bearing reliability.

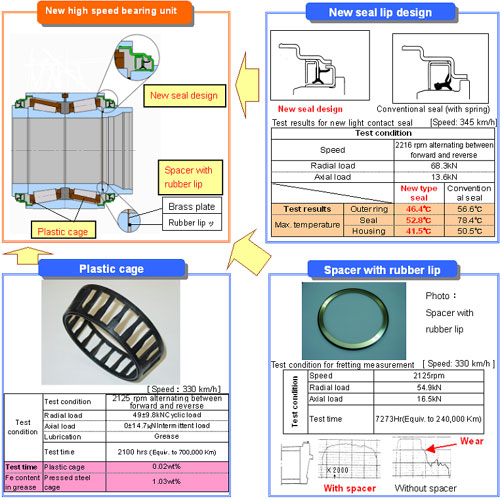

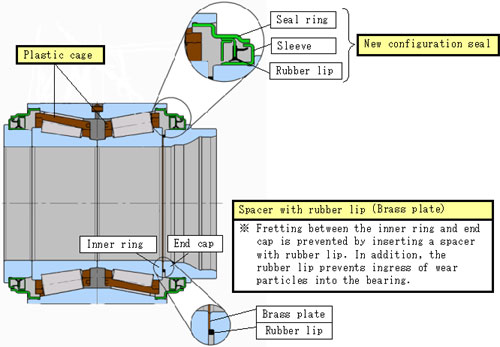

In response to these demanding requirements, NTN has developed a new high speed bearing unit (New RCT Bearing) for railroad journal applications. NTN developed and applied new technologies including a special plastic cage, a spacer with rubber lip, and a new seal lip design. This enabled an extended maintenance interval period to 1.2 million km as compared to 600,000 km of the conventional design.

| (*) | The RCT Bearing (Rotating end Cap Tapered roller Bearing) enables a reduction in life cycle cost by extending the maintenance interval period. RCT is a registered trademark of NTN corporation and NSK corporation. |

[ Features ]

Bearing maintenance interval period is double that of a conventional bearing.

| (a) | Special plastic cage | |

| Longer lubrication life is achieved by means of curbing the generation of wear particles from the cage by use of a special plastic material. The cage is also shock resistant. | ||

| (b) | Spacer with rubber lip | |

| Longer bearing life is ensured by reducing the fretting between the inner ring and end cap due to dynamic bending of the journal. It also prevents ingress of fretting wear particles. | ||

| (c) | New seal lip design | |

| Lubrication life is extended by lower temperature rise (20°C reduction at the seal at an operating speed of 345 km/h) while maintaining the same sealing performance as a conventional seal. | ||

[ Application ]

| Railroad journal support bearing |

[ Product photo ]

New high speed bearing unit for railroad journal applications (New RCT Bearing)

[ RCT Bearing ]

| Rotating end Cap type Tapered roller Bearing |

[ Sales points ]

[ Technical approach ]