|

|

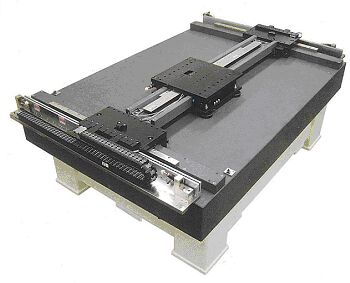

“Large-Size Precision XY Table” for Large Glass Substrate Plates

To meet the expanding demand for flat panel displays (FPD), NTN Corporation has succeeded in becoming the first company to develop a “Large-Size Precision XY Table” for large glass substrate plates. This table is used for positioning inspection and manufacturing equipment for 6th generation (1500x1800mm) glass substrates.

FPD manufacturers are always trying to make flat panel displays larger, and have recently shifted from the 4th generation (730x920mm) panels now in general use, to larger 5th (1100x1300mm) and 6th (1500x1800mm) generation FPD's. However, the longer strokes and higher mounting loads that would be required of conventional laminated XY stages make it impossible to meet the demands for table speed, resolution, speed fluctuation, positional accuracy, and straightness necessary for production of the new large size substrate plates.

NTN's new “Large-Size Precision XY Table” for large glass substrate plates uses a special in-house technique for integrating newly developed air bearings and non-contact linear motors with dedicated flat cable connections. The new technology in NTN's new product meets all the demands required in the manufacturing of 6th generation FPD glass substrates. Even now, new models are on the drawing board for the larger 7th generation glass substrates and beyond.

FEATURES

Delivers all functions necessary for equipment used in the manufacturing & inspection of 6th generation glass substrate plates.

Performance comparison with 4th generation XY tables:

- Table speed: 500mm/second (3 times faster than previous tables)

Resolution: 0.025μm (40 times better than previous tables)

- Speed fluctuation: Within 0.1% (1/10th that of roller types)

- Position accuracy : Within 2μm, (10 times better than previous tables)

- Straightness : Within 3μm, (About 10 times better than roller types)

|

|